In recent years, 3D printing has seen a rapid spike in popularity because of its use in various fields, such as construction, manufacturing, and healthcare. Because of this, more and more companies are finding ways to make 3D printing efficient and affordable. However, there’s still the matter of filaments to consider.

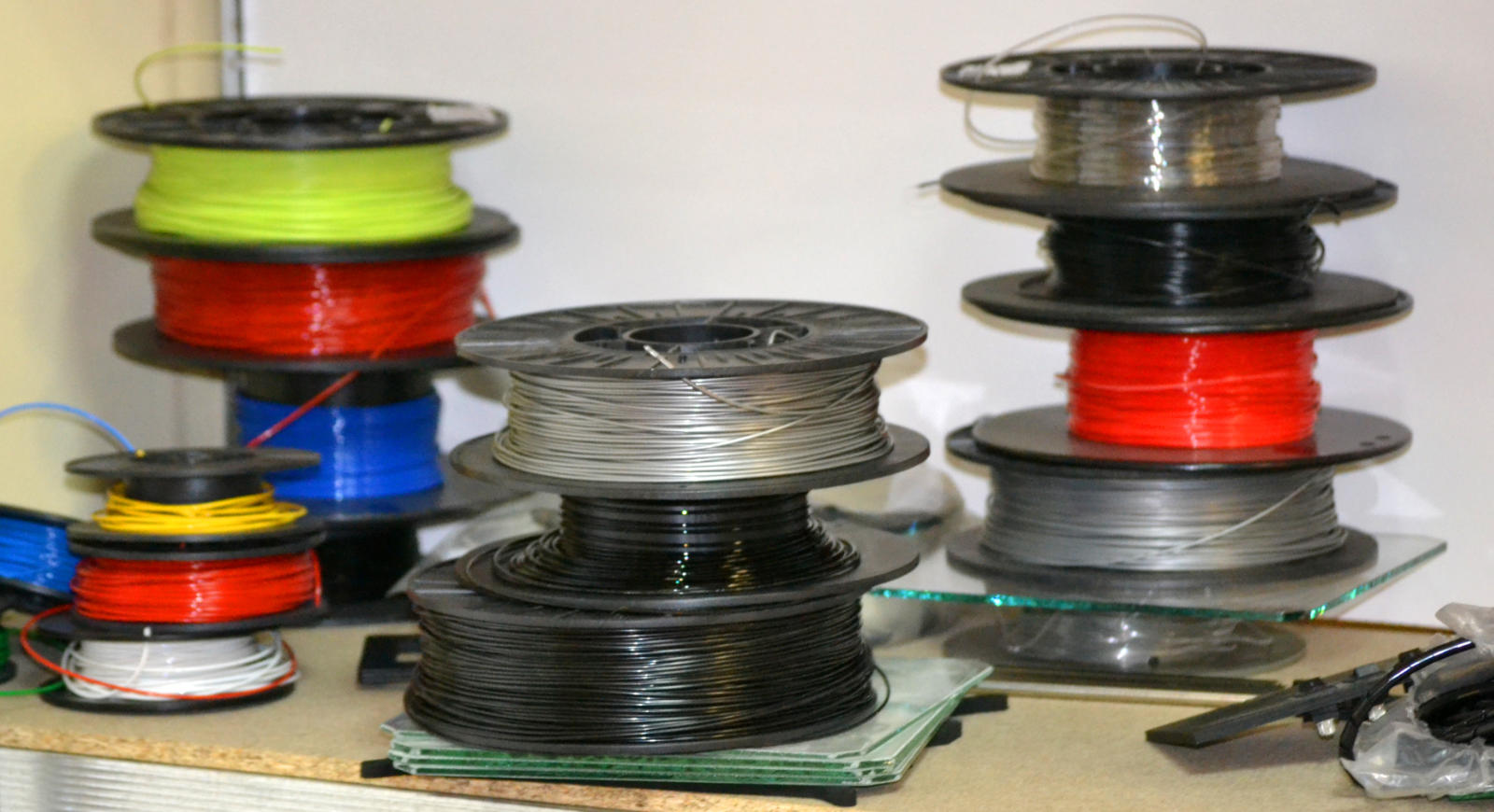

3D printing filaments are the primary material used to make 3D printed objects, and choosing the appropriate material for the job calls for extensive research. Different types of filaments are used in 3D printing, but two of the most common are polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS). Both materials are widely used in the 3D printing industry because of their properties, but knowing the differences between them can help you make the best decision for your product.

More about PLA

PLA is a bioplastic, meaning it’s made from renewable plant materials such as corn, potatoes, and sugarcane, as opposed to petroleum. Creating PLA is relatively simple, as it’s the polymerisation of lactides made from natural sugars. PLA filaments are not only biodegradable and renewable but also hard and strong, making them perfect for use in applications such as architecture and structured designs.

PLA is a biodegradable thermoplastic, so it’s commonly used for 3D printing in applications that require composting, such as biodegradable products and packaging, or in designs that require an aesthetic such as jewellery.

PLA is a polymer that undergoes annealing, meaning it will become softer when heated and re-harden when it cools. Because of this, PLA is ideal for printing parts that will be handled frequently.

More about ABS

ABS is also made from lactic acids and other substances, but it is a copolymer rather than a polymerisation. It also can be recycled along with other thermoplastics. ABS is also a petroleum-based plastic and is harder and more flexible than PLA. ABS can be purchased in flexible, rigid, or semirigid varieties and is known for its durability and resistance to impact. Because of its high impact resistance, ABS is the preferred material for applications that will be made to be used in harsher conditions.

In addition, ABS is less brittle and has higher tensile strength than PLA. ABS also does not become soft when it cools and is ideal for situations where parts that will be handled or used frequently need to be printed.

Comparing PLA and ABS

Both PLA and ABS come in various colours, making customising parts simple. They also have similar melting temperatures, with ABS slightly higher at about 235°C and PLA at about 210°C. ABS is also resistant to solvents and weak acids and alkalis and is not recommended for prolonged contact with food.

However, PLA is more susceptible to acids and alkalis. PLA is also more flexible than ABS, making it ideal for printing parts that need flexibility and are more likely to be handled. PLA is softer and more flexible than ABS, making it suitable for applications requiring flexibility.

As for cost, PLA generally costs more than ABS. This is because PLA is a bioplastic made from plants that need to be cultivated. In addition, ABS is more likely to be recycled than PLA, resulting in a lower manufacturing cost.

What Should You Choose?

Ultimately, choosing what filament to choose depends on what you’ll create. If you’re making parts that will likely be handled frequently, such as jewellery and figurines, PLA is ideal because it is flexible and soft and can be printed at a higher temperature. However, if you’re looking for parts that will be used and placed in applications where they will be used in harsher conditions, ABS is a better choice because of its durability.

Conclusion

The benefits of 3D printing are endless, and the number of applications is only increasing. As technology advances, we can expect to see it improve. Knowing the difference between filaments can help you make the right choice, ensuring you can achieve your desired results more efficiently.

If you’re looking for 3D printing companies in the UK, 3D Quick Printing can help you! We use different materials to ensure that your product will come out in top quality according to your specifications, all for affordable prices. Simply go to our website to get a quote!

Recent Comments