There are several factors to consider while designing for quick prototyping. It is essential to understand the different facets of 3D printing to choose the best material and equipment for your item. Here is a list of the top seven items to think about when prototyping:

1. The Final Product

The application of your product should be at the forefront of your rapid prototyping selections. Suppose your prototype must duplicate the cosmetic appearance of the final product. In that case, you may need to use a finer resolution technology and material, or the prototype may need to be post-processed for aesthetics. If you require your prototype to perform exactly like the final product, that is where technologies that offer robust materials and ideal tolerances come into play.

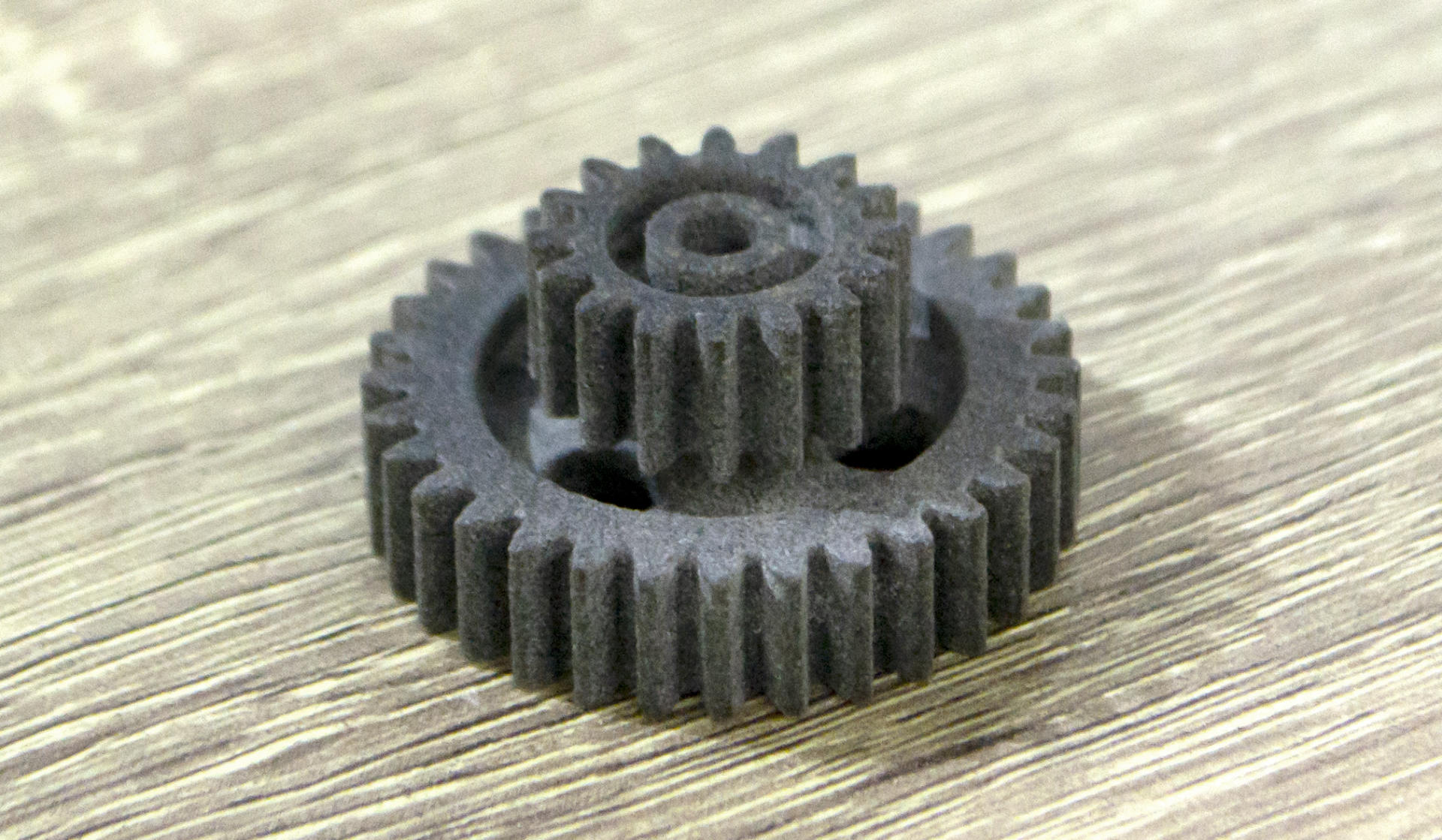

2. 3D Printing Technology

A large part of the technology’s capability lies in the dimensional accuracy and tolerance ranges. 3D printing technology can have a high or low resolution, so the desired dimensions and tolerance levels need to be considered. The material choice will depend on the part’s function and how much post-processing is required.

3. The Function of the Prototype

The functionality of your product, as well as your prototype, is of utmost importance. How will it be used, and is it required to withstand certain conditions? Is it being tested for fit and form, pressure, stresses – and the like? Does it need to be ergonomically friendly? Part size, material properties and additive manufacturing processes will be considered.

4. The Manufacturing Process

What is your process? Is it in-house or outsourced? Do you require a finished product or just a prototype? Is the process a one-off, or do you need to repeat the process repeatedly? Each of these questions should be answered to get an understanding of the best material and process for your prototype.

5. Material Properties

Material properties are an important part of your prototype; they play a vital role in the decision process. Material properties affect the part’s geometry, function and durability. Considerations should be made on whether or not the material needs to be post-processed. If aesthetics are important, this will also be something to take into consideration.

6. Material and Design Strength

You have to take into consideration the material and design strength. Some materials are simply not practical to 3D print, while others are easier to 3D print but may not suit your application. It is also important to ensure that the additive manufacturing process will allow for the strength required for your prototype.

7. Post-Processing

Some materials require extra steps to be made after printing. These post-processing steps may include sanding, drilling, polishing, milling, etc. The material and process used for rapid prototyping should allow for post-processing to be completed to obtain the desired aesthetics and functionality.

Conclusion

Prototyping is a critical part of the design process, and with the right material and technology, you can create the perfect prototype in the least amount of time.

The material and process used must allow for post-processing to be completed to obtain the aesthetic and functionality required. In addition, it is important to consider the end product’s functionality and how it will be used. It is also important to take into consideration how it will be manufactured to determine what process and material are best suited.

3D Quick Printing offers high-quality 3D printing services to help individuals get the models they need for any project. If you’re interested in rapid prototyping help, reach out to us today!

Recent Comments