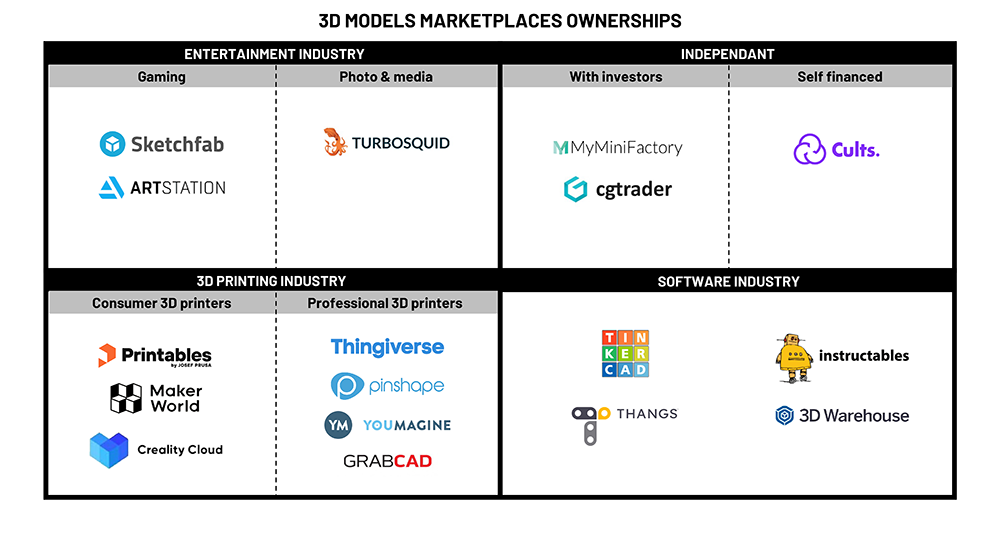

Status report on the dependencies and ownerships of the different 3D model marketplaces linked to the 3D printing market.

Status report on the dependencies and ownerships of the different 3D model marketplaces linked to the 3D printing market.

3D printing has been a relatively quiet revolution across multiple sectors. It is commonplace in the aerospace industry, and the automotive sector, and gaming fans looking at the latest sister site casino guide may not realise it but much of the gambling equipment at their favourite local casinos, from poker chips to craps dice can be produced through 3D printing.

When Cults started we would often share Cults designs in the r/3DPrinting thread to promote the work of the best designers on our platform, especially for the designers who didn’t have the reflex to use Reddit. Since this was a kind of advertising for our website, the moderators asked us to stop, which we did.

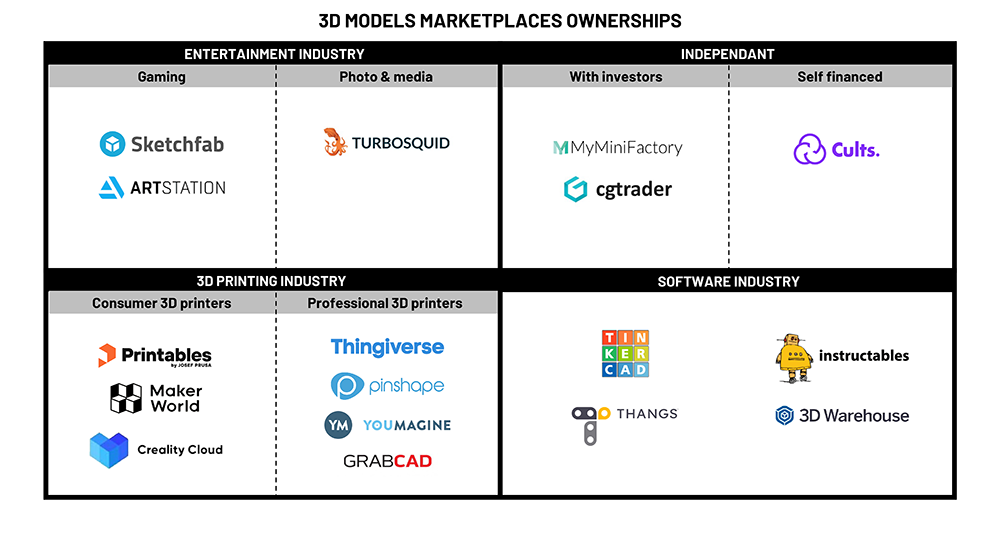

From the humming workshop floors to cutting-edge design studios, the resonance of 3D printing is unmistakable. Not only has this technology revolutionized prototyping, but it’s also recast the entire manufacturing paradigm. Initially, we marveled at the single plastic constructs, yet, today’s landscape brings a dazzling array of materials and colors, showcasing a robust evolution.

In the bustling digital marketing arena, a revolutionary technology is shaking up traditional practices: 3D printing. While its transformative impact is widely acknowledged in sectors like manufacturing and healthcare, its potential to reshape digital marketing strategies is an emerging frontier.

Anycubic is thrilled to announce its eagerly anticipated 8th-anniversary celebration, scheduled for September 2nd. As part of the celebrations, Anycubic is staging the inaugural A-Creators Fest. This year’s festivities will span an entire week, uniting esteemed users, revered influencers, and media partners from across the globe.

In the sphere of engraving and cutting technology, new innovations are constantly being introduced, reflecting the dynamic evolution of both industrial applications and consumer-level creativity. Among the latest developments in this field, the AlgoLaser Alpha 22W laser engraver stands as a noteworthy example.

Technology has changed how the world works. Now, people enjoy the convenience of buying a product that they like with their mobile phones at home and so much more. Furthermore, the internet has made possible the easy exchange of ideas, which in turn revolutionized how individuals and groups interact with one another.

Not long ago, 3D printing seemed like another future tech¾creating tangible items on your desktop just with design software and a specialized printer. These days, you can score a 3D printer for under $250 and buy multi-colored reels of media for under $25. This brand-new accessible technology opens up a world of possibilities for game enthusiasts seeking to level up their gaming experience.

3D printing experts Tiertime, recently announced the launch of Cetus2, an advanced printer that uses an innovative new print head design making it possible to use one nozzle and switch seamlessly between multiple materials and colors on the fly. No need for nozzle alignment and no need to stop or print purge tower, Cetus2 is time and material saving, and capable of fast material switching during printing. This unique time & material saving feature has never before been possible with traditional FDM 3D printers and opens a new world of creativity for users. This exciting new product is perfect for makers and professionals who wish to elevate their 3D printing efficiency and creativity. [Cetus2](https://s.zbanx.com/r/v3dNIveMfPao) is available now.

“Slow is fast, a good product is always worth the wait.” On 28 June 2023, Ortur finally launched the long-awaited **Ortur Laser Master 3 LU3-20A 20W laser engraver**. ORTUR launched the OLM3 LU2-10A 10W laser engraver last year and received positive feedback from customers in different industries. Meanwhile, the laser engraving market had been eagerly waiting for the launch of the “Ortur 20W”.

3D printing is injecting fresh lifeblood into the veins of an age-old industry. As the gears of technological evolution grind inexorably forward, the alchemy of three-dimensional printing is reshaping toy manufacturing into an art form.

Recent Comments