Designing equipment, footwear and accessories

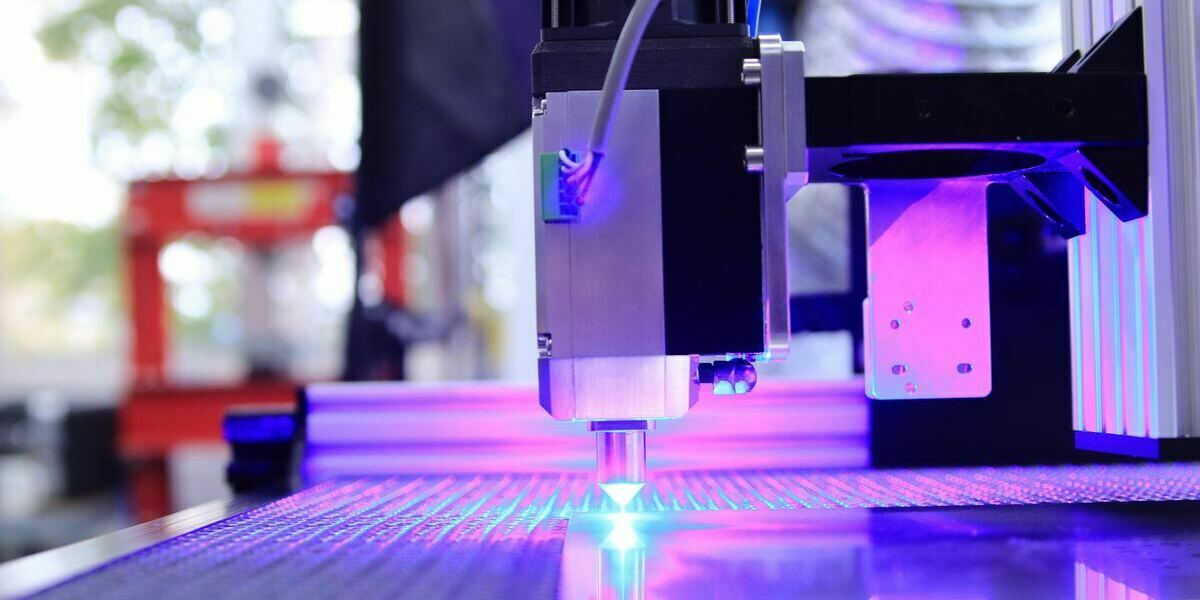

Before 3D printing, sports design and fashion companies would use hand-drawn prototypes and blueprints and, more recently, digital computer programs to construct a whole host of accessories, ranging from football helmets to soccer boots and shinpads. You can even use a 3D printer to print off accessories such as emergency sports whistles if you need one quickly and don’t have time to take a trip to the store.

However, ever since 3D printers became accessible to many of these companies, they have supported design projects from the beginning phase. Prototypes can be printed at full scale to allow designers to make adjustments and get a feel for their designs in a way that was never before possible.

Prominent names in sports design, like Nike and Adidas, are able to liaise with the global superstars they have branding deals with. Instead of sending them paper-based copies of the shoe, tracksuit or accessory designs, they can use a 3D printer to provide a more accurate model for them to examine.

Paralympian performance and prosthetics

Prosthetic legs are an incredible feat of design engineering. Now, 3D printers are able to produce scaled models of prosthetic limbs, which has allowed some of the world’s top Paralympians to benefit from the advances made in this technology. The detailed levels of research and development that went into prosthetic limb design before the ingenuity of 3D printers was astonishing.

Since becoming nearly commonplace, 3D printers have transcended these capabilities and expanded what designers can do, essentially adding a new dimension and allowing Paralympians to receive prosthetics that are far more customized to suit their specifications.

Some of the top performers at the most recent Paralympic games used prosthetic limbs and features designed predominantly through 3D printers. The positive impact this has had on this specific area of the sports industry has been immeasurable. As advances continue to result in significant developments, it is one of the most exciting elements of 3D printing and could completely revolutionize the Paralympics moving forward.

A carbon-friendly approach

As more businesses adopt ways to bring down their carbon footprints, many within the sports industry use 3D printers to spearhead their carbon-friendly approach. By using these ingenious new devices, design companies are able to use specific, greener alternatives to deliver the types of prototypes we discussed before.

Compared with traditional designs, which would use a significant amount of plastic and other non-renewable materials, 3D printers use renewable and environmentally friendly materials to design prototypes, minimizing the impact of their carbon footprint. As there’s now such a massive emphasis on bringing down emissions, any idea that facilitates this will be encouraged by central governments and sports governing bodies.

This greener approach also coincides with a greater scope of ideas, so it is a no-brainer for many companies to shift from expensive and cumbersome computer graphic programming software to the increased enhancements of 3D printing.

Conclusion

Any invention that can streamline a current process, make it more carbon friendly, and allow Paralympians better access to essential and highly innovative prosthetic designs will inevitably play a considerable role in the sports industry moving forward. The impacts have already been monumental, and as research ramps up, more technology companies are working with those in the sports industry to find the best solutions. 3D printing will continue to have an increasingly significant and influential impact on the sports industry in the future.

Recent Comments