This week 3D Printing Industry joins the additive manufacturing world in Frankfurt for the return of one of the major events on the calendar – Formnext.

A vital component of the expo is the annual start-up challenge, with winners selected for free participation in the trade show including a pitch event on Day One. All week we will be profiling the winners. In this article, Azul 3D’s CEO Cody Petersen gives more information about Azul 3D.

3DPI: When was your company founded and where are operations based?

Cody Petersen: Our company was spun out of the lab of Chad Mirkin, a chemistry professor at Northwestern University, in 2017. Co-founder James Hedrick, Ph.D., was a graduate student in the lab, and co-founder David Walker, Ph.D., was a postdoctoral fellow. Together, they developed the high-area rapid printing (HARP) technology that formed the foundation for Azul 3D’s technology stack. Today, we are headquartered in Skokie, Illinois.

3DPI: Can you tell us more about your team’s background and experience with AM?

CP: We have a diverse group of experiences that make up our team. We combine traditional manufacturing expertise with industrial 3D printing and stir in a bit of ingenuity and creativity to make the impossible possible.

As CEO, I bring a background of operations and product development leadership in manufacturing. Our chief revenue officer, Tuan TranPham, has more than 18 years of experience in additive manufacturing and has been recognized with the Additive Manufacturing Users Group’s Distinguished Innovator Operators (DINO) award. Our CFO, Shane Glenn, has more than 16 years of experience in additive manufacturing. Our board members John Hartner (CEO of metal additive manufacturing firm ExOne) and Vince Anewenter (director of the Rapid Prototyping Consortium at the Milwaukee School of Engineering) round out our additive manufacturing experience.

The team is anchored by the scientific expertise of co-founders David Walker and James Hedrick. Together, our goal is to revolutionize manufacturing to make good on the promises of 3D printing.

3DPI: What does your company do?

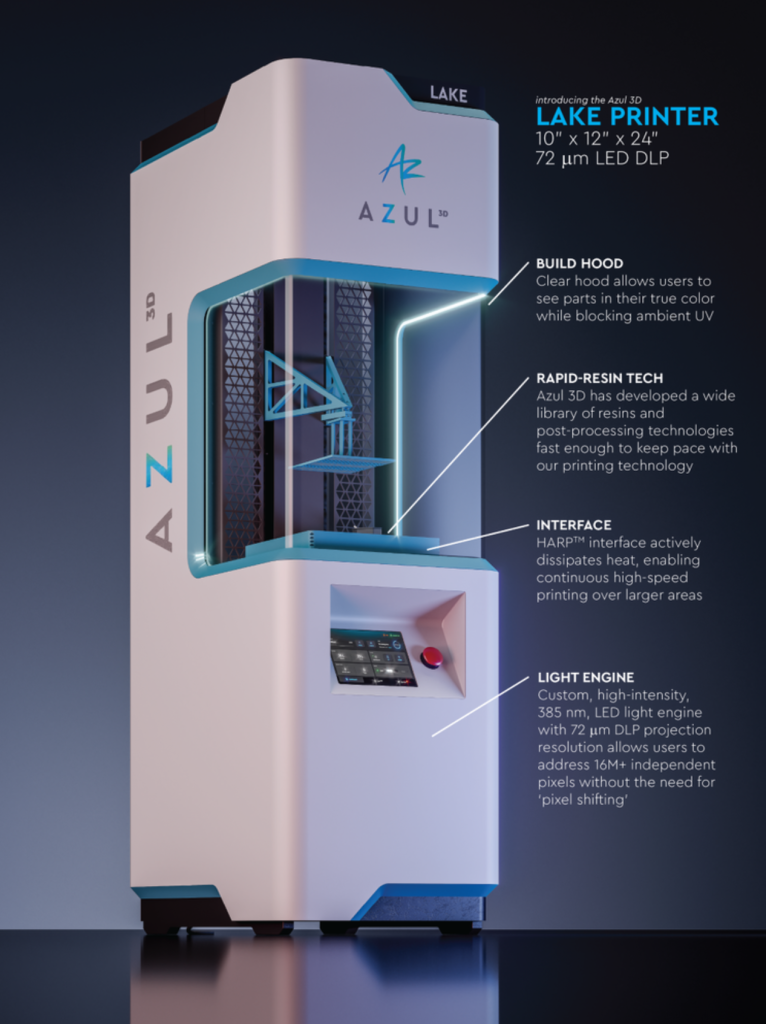

CP: We offer our clients a full-stack solution to their manufacturing needs, partnering with them on design, materials, printing, and post-processing. This fall, we launched our first commercial product: the LAKE printer, which can print large complex geometries at incredible speeds, using proprietary materials suited for a wide range of products. LAKE’s unique interface dissipates heat, enabling continuous high-speed printing over large areas.

In addition to LAKE, our chemistry group designs proprietary resins that are strong, durable, customizable, and compatible with high throughput printing across a wide range of material families.

3DPI: How does your company fit into the additive manufacturing ecosystem?

CP: Our technology helps manufacturers consolidate parts, create new geometries, secure a digital inventory, support localized manufacturing, and design completely customizable products. Our printers, the LAKE and future printers, will represent a new paradigm in the industry. We will be the go-to solution for manufacturers of industrial, consumer, and automotive goods.

Azul 3D will fill the gap between traditional additive manufacturing (prototyping, molds & tooling, and limited production runs) and traditional mass manufacturing of plastic goods. Our technology and product portfolio fill this unmet need in today’s manufacturing ecosystem.

3DPI: How would you describe the roadmap for your enterprise in the coming years?

CP: We will continue to develop our material library to create a true continuum of materials across multiple families that can be printed with our printers. We will be rapidly scaling our printer capacities to increase production throughput and increase the spectrum of parts that can be printed on our system.

3DPI: Is there anything else you would like our readers to know?

CP: Our technology fills the fundamental gap in today’s market between prototyping and injection molding. Filling this gap comes from leveraging additive manufacturing’s inherent advantages while offering our customers the throughput, economics, part quality, and material diversity that is enabled through traditional manufacturing.

We believe the new geometries that additive manufacturing enables must be paired with bespoke materials to create a product that is ready for industrial and consumer use. We create completely customizable polymers that can be as flexible, rigid, soft, or strong as needed, and can be formulated to match exact colors and hues. We are excited to show the world our innovations in materials.

Meet the Formnext Start-up Challenge 2021 Winners

If you are attending Formnext, make sure you visit the Start-up Area (Hall 12.0, B81). The official award ceremony is to take place on Tuesday, 16 November 2021 from 3:00 p.m. on Formnext’s AM4U stage (Hall 11.0, E72).

The 3D Printing Industry will be in Frankfurt all week, so make sure you say hello if you see us!

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing.

You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs to find or advertise additive manufacturing jobs.

Recent Comments